Metallic Surfaces

Metallic Surfaces - Sol-Gel Hybrid Systems

Since 2005, we have been developing, formulating and producing functionalised special coating systems for metallic & mineral surfaces.

Another focus of our development work is the special coatings with antimicrobial effect on metal surfaces, mineral and plastic surfaces.

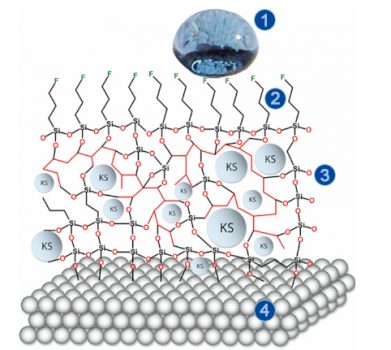

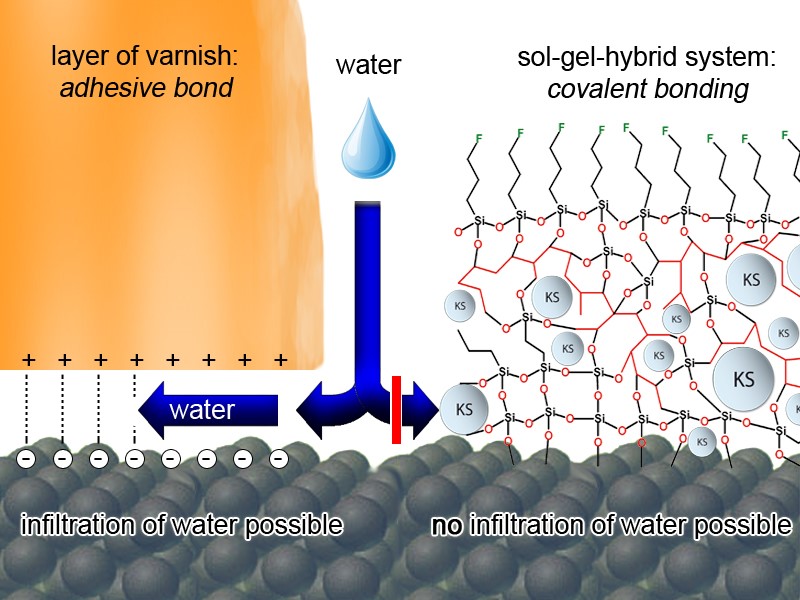

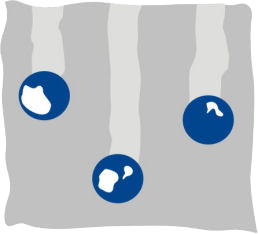

Inorganic - organofunctional sol-gel hybrid systems for metal surfaces

Examples

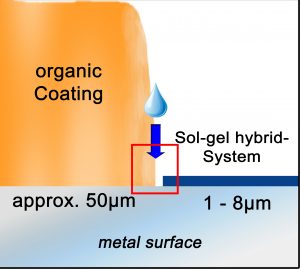

Aluminium 3003

Cr-free pre-treatment

3 µm sol-gel hybrid system

Coil Coating

60 sec curing at 260 °C

Results

> 1000 h acid spray test

No delamination at the scratch

Easy-to-clean effect

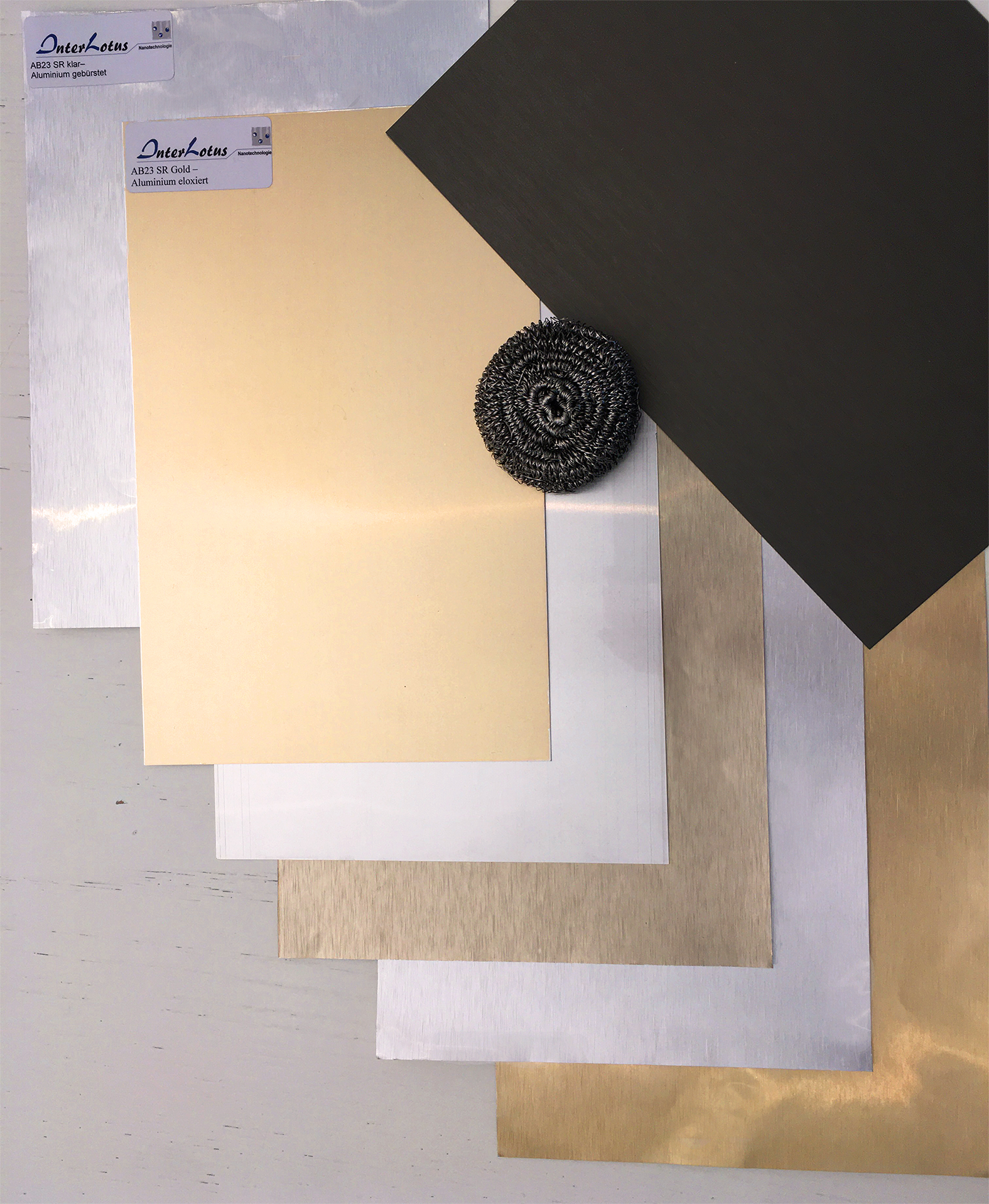

– High-performance thin layer coatings

– Transparent, glazing or coloured covering

– Reliable corrosion protection at low film thicknesses

– Short curing time (coil coatable)

– Functionalised surfaces

– High coverage

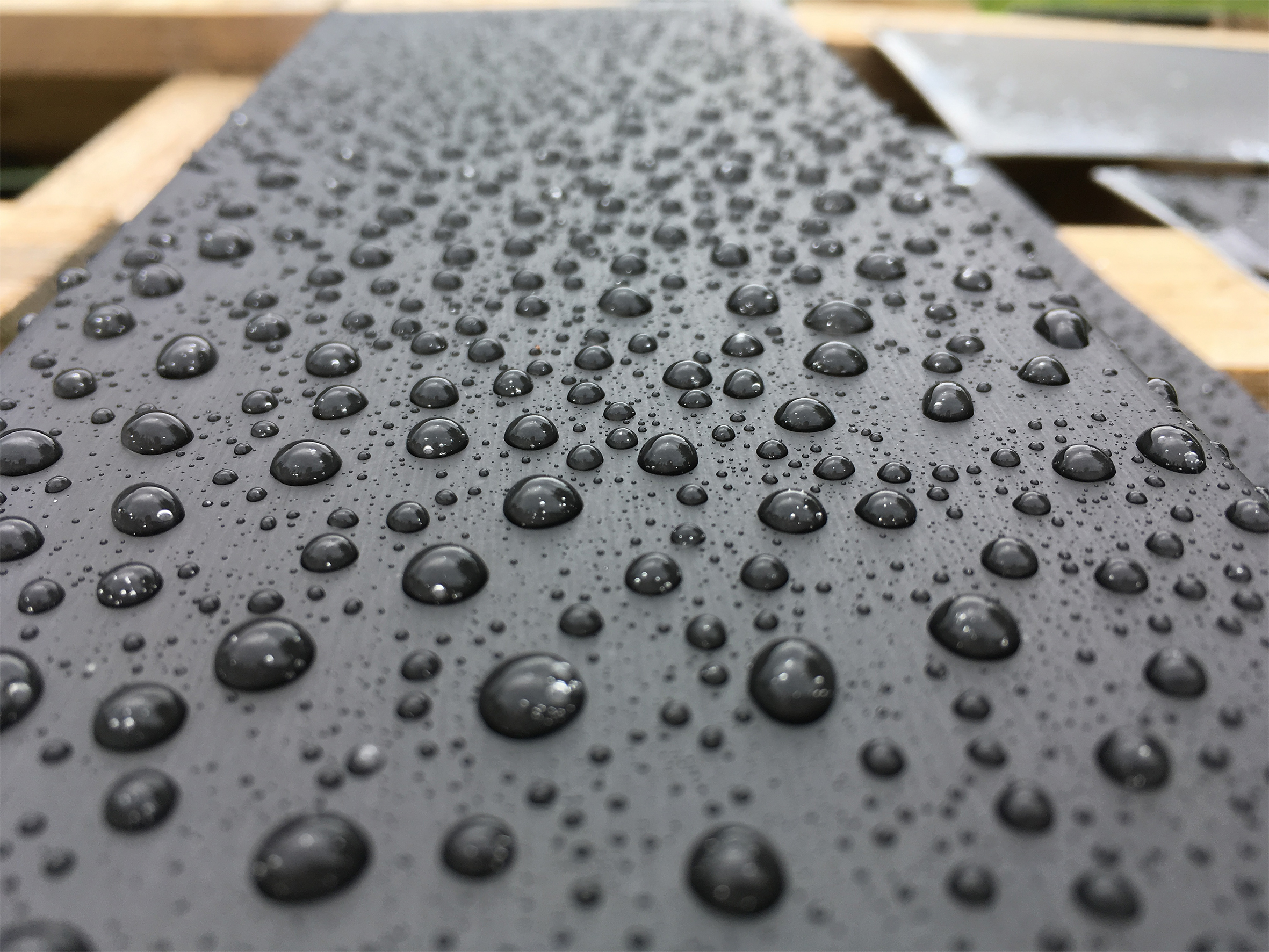

– Easy-to-clean effect

– Heavy metal free

– Very high UV resistance

– Solutions for primer and topcoat applications

– Smooth levelling

Advantages of InterLotus coating systems

Metallic surfaces

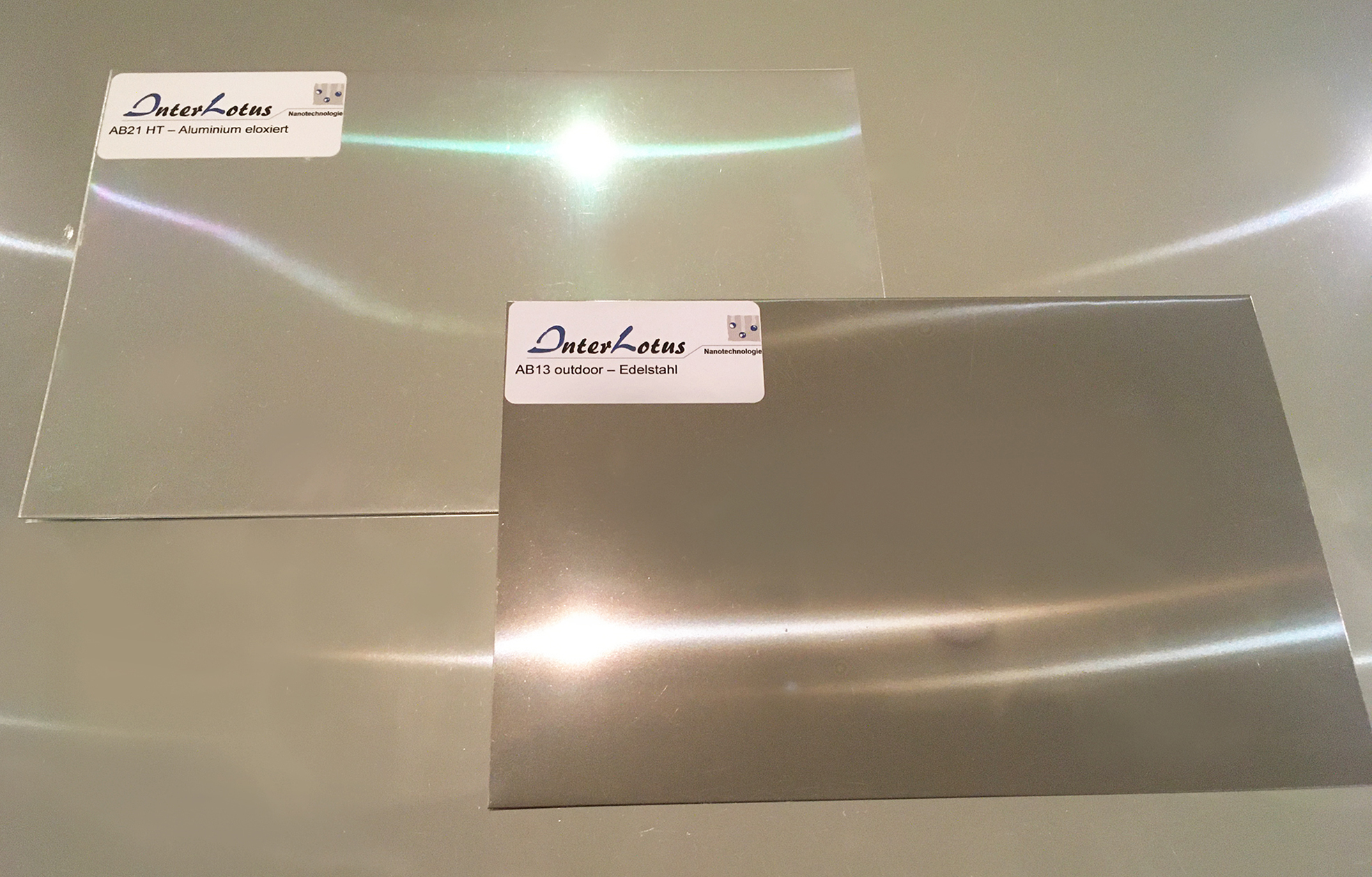

Interlotus aluminium coatings are preferred by industrial manufacturers and users on coil coating lines. They offer multiple advantages for a finished and high-quality aluminium surface.

– High transparency

– Glazing

– Anti-fingerprint

– Easy-to-clean

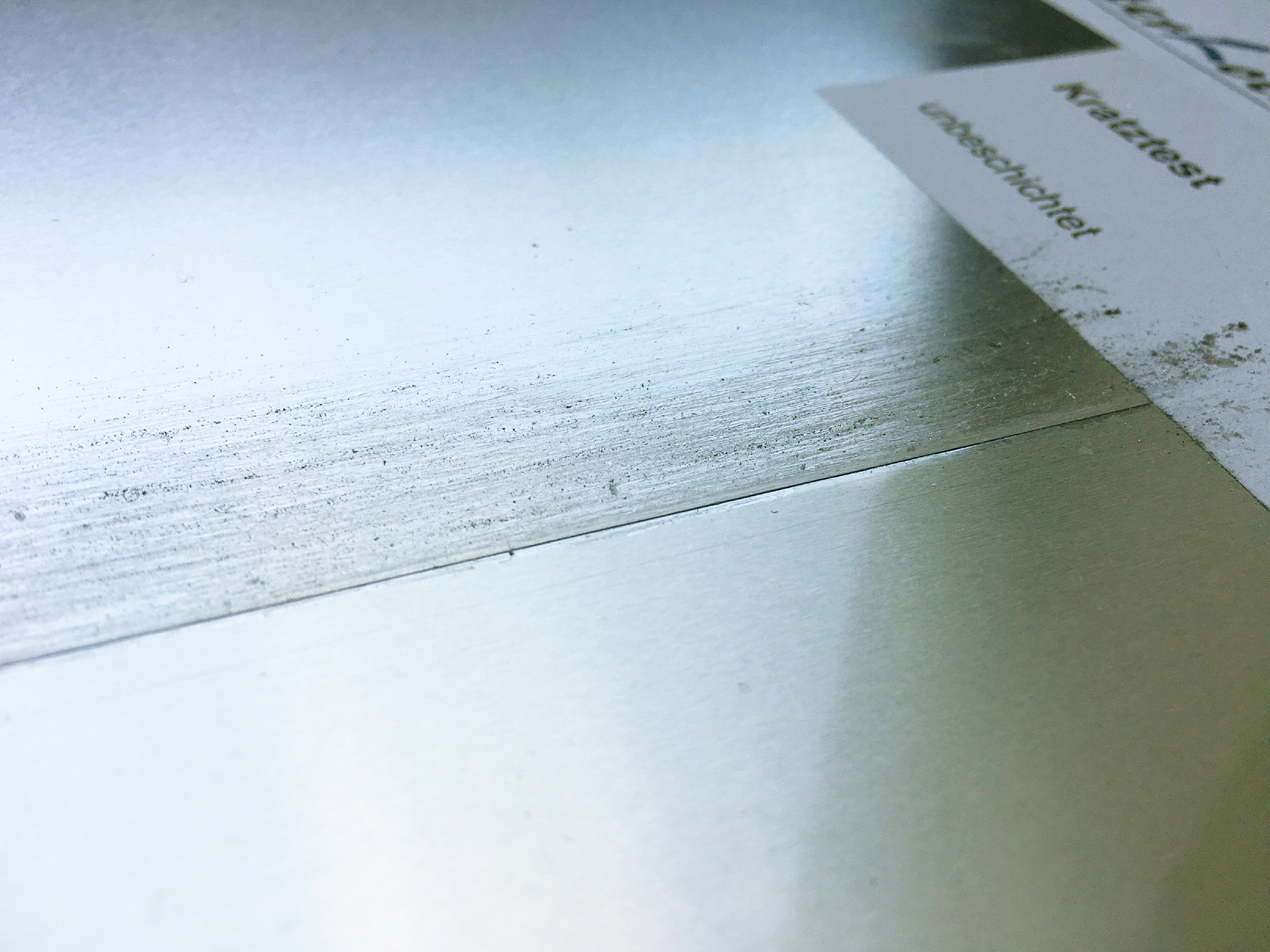

– Scratch resistance

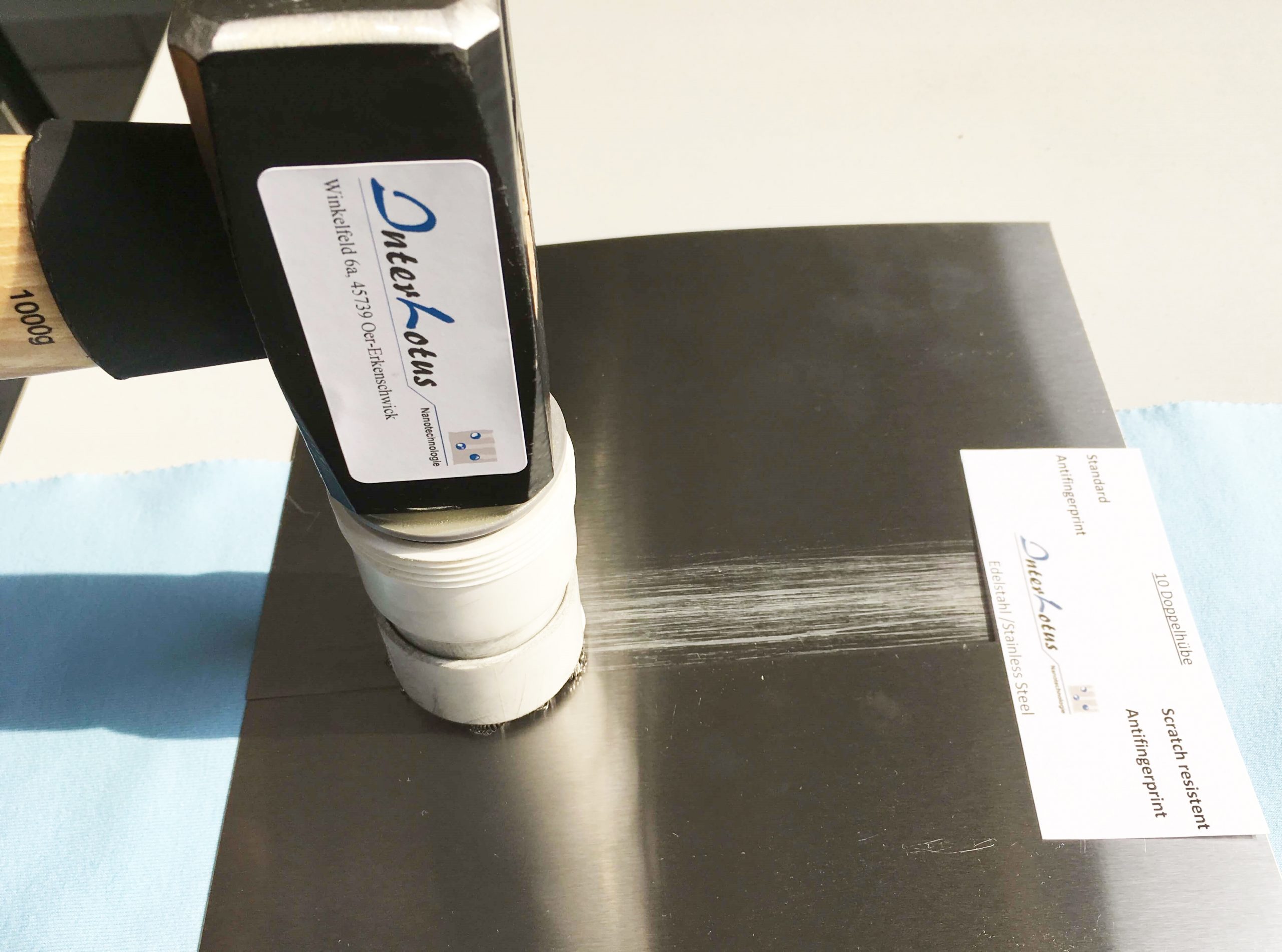

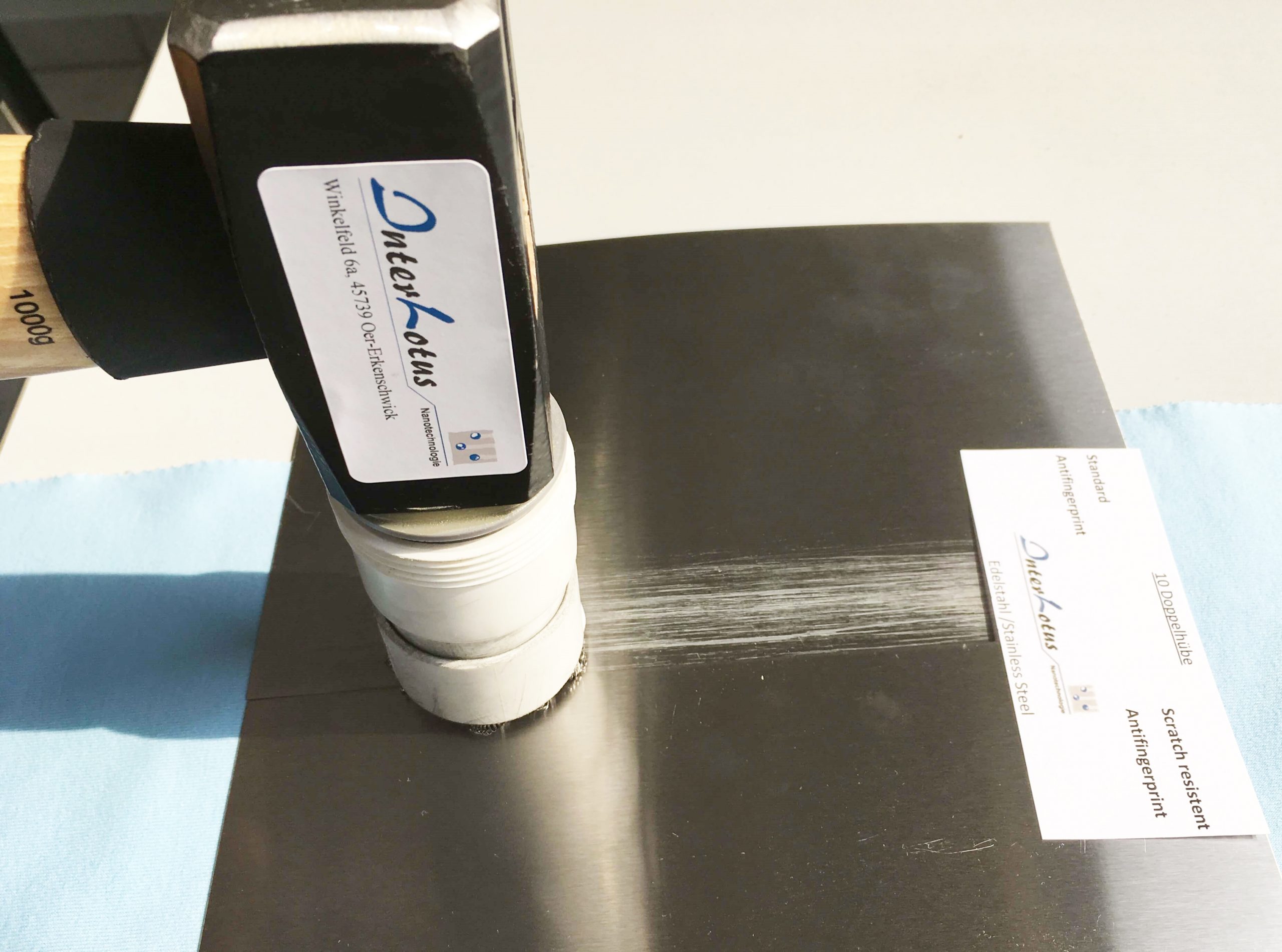

Stainless steel in various qualities is “quite soft” and very sensitive to scratches and is therefor foiled before further processing. Usually plastic foils are used. At the end user, the foil has to be removed and the sensitive surface comes into operation.

Therefore, stainless steel surfaces should already be protected before foiling. Interlotus products protect against scratches, facilitate cleaning with an easy-to-clean effect and prevent unsightly fingerprints with an anti-fingerprint effect. If required, the stainless steel coating can be equipped with an antimicrobial effect.

Anti-fingerprint & easy-to-clean properties

Both properties create hygienic advantages in

clinically demanding situations.

Advantages of Interlotus

coatings on stainless steel:

Scratch-resistance

Easy-to-clean

Antifingerprint

Antimicrobial

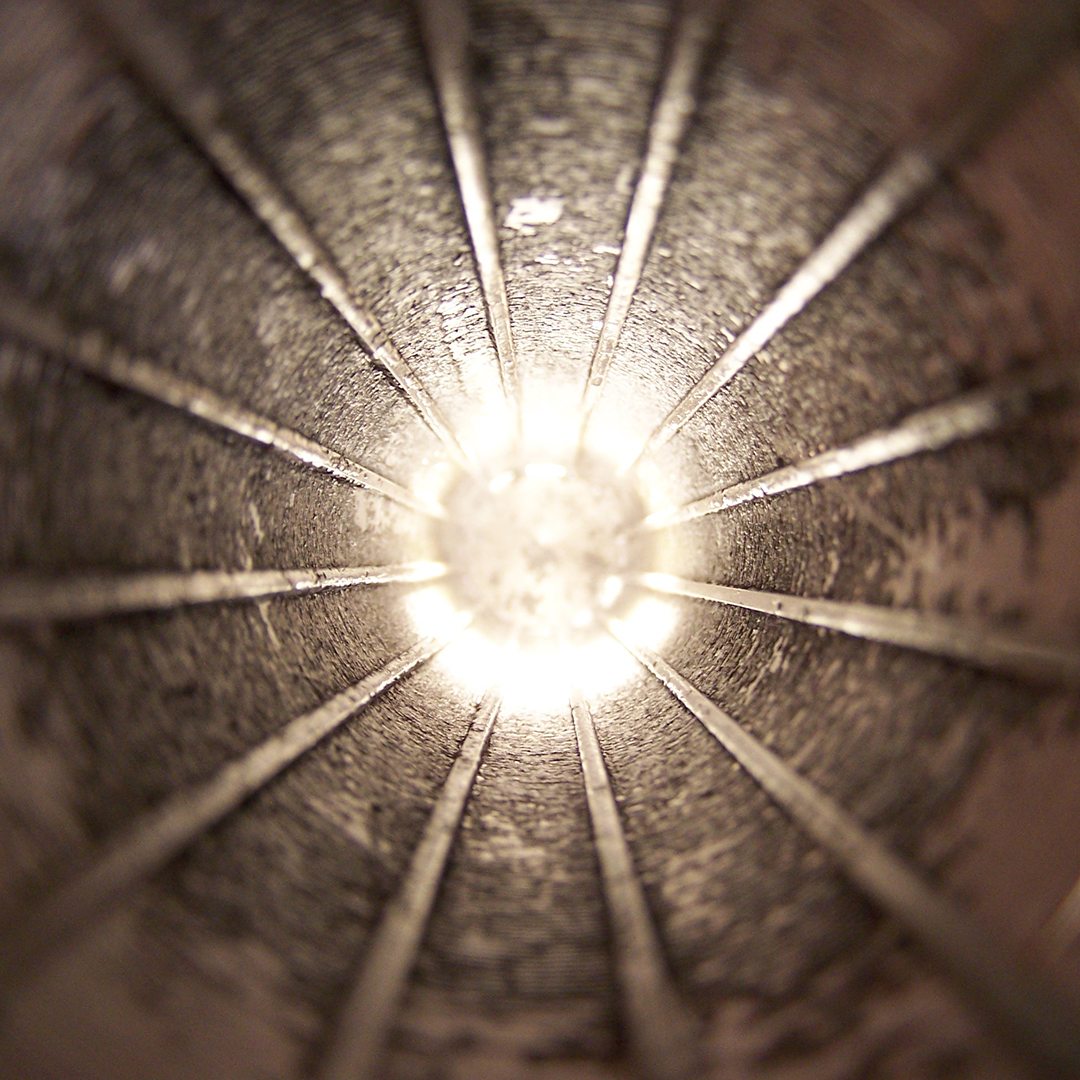

Hot-dip galvanised and electro-galvanised steel have more or less medium to good corrosion protection, depending on the zinc protection layer. For sophisticated and long-life surfaces, we suggest our additional ultra-thin, paintable conversion coatings. These are coil coating products that can significantly improve corrosion protection and sliding properties with very thin layers ≤ 1 µm.

Interlotus products for galvanised steel have the following properties:

– Applicable conversion coating

– Various corrosion protection classes from temporary to 1000 h NSS

– Corrosion protection at S ≤ 10 µm, 1000 h NSS

– Primer function

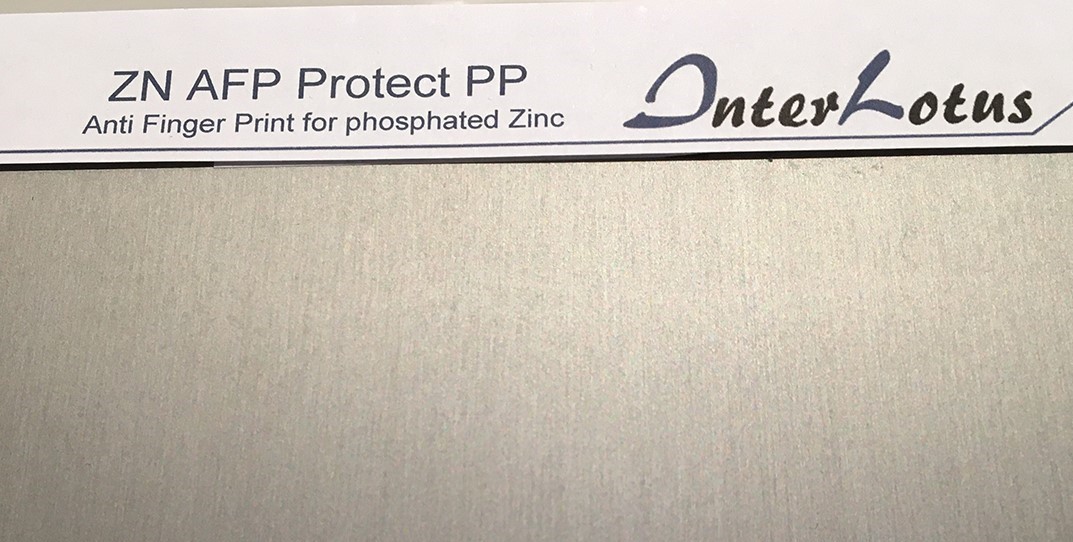

– Anti-fingerprint

– Improvement of sliding properties during further processing

– Customer-specific colours / colour settings

With these products, we create thin-film added value that contributes positively to production improvement, durability and environmental protection.

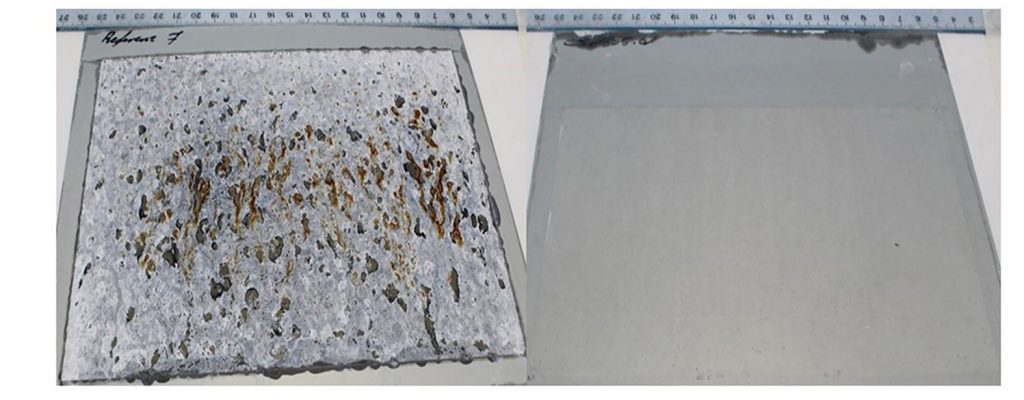

Interlotus Produkt – Konversil®

Uncoated sheet

after 48 hours in the

salt spray test

Coated sheet

after 200 hours in the salt spray test Coating less than < 1µm

Interlotus Konversil®

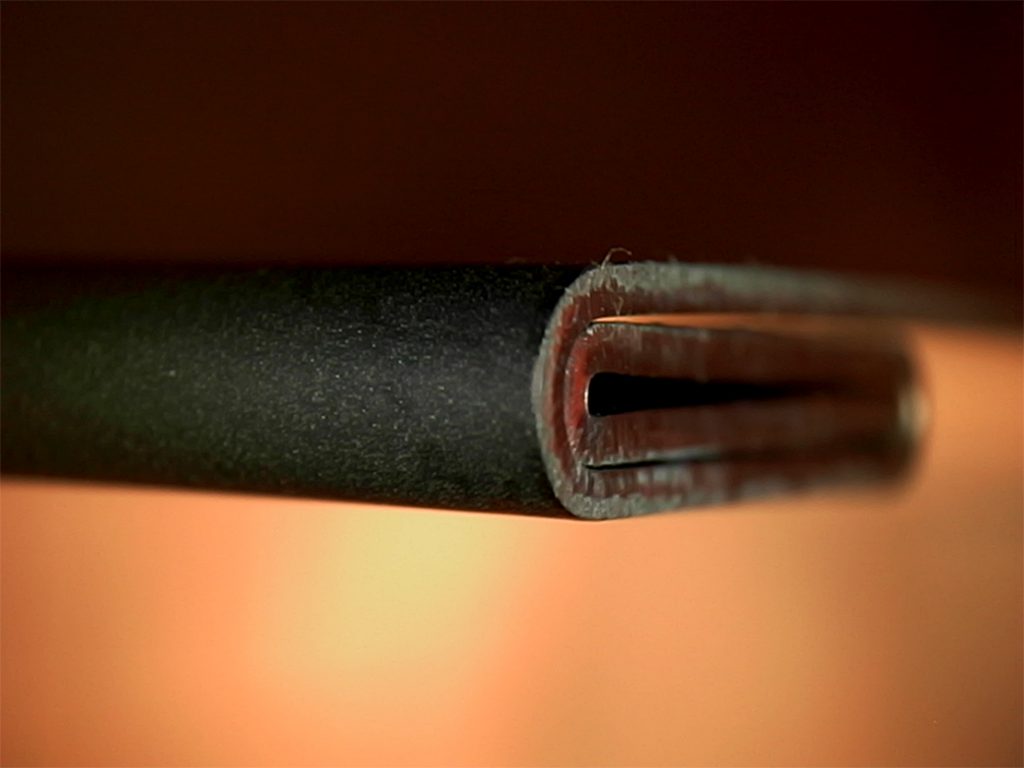

Steel pipe - temporary corrosion protection

The aim of temporary corrosion protection is to achieve a sufficient corrosion protection effect on the components during the production process, storage and transport.

Zinc surfaces are known for their natural long-term resistance. They pass through the natural process of ageing, Patina education with slight optical changes. In order to create these natural processes in an artificially controlled process, technically complex conversion layers or phosphating’s are applied to the zinc material. These protective layers are in turn sensitive to mechanical damage and corrosion.

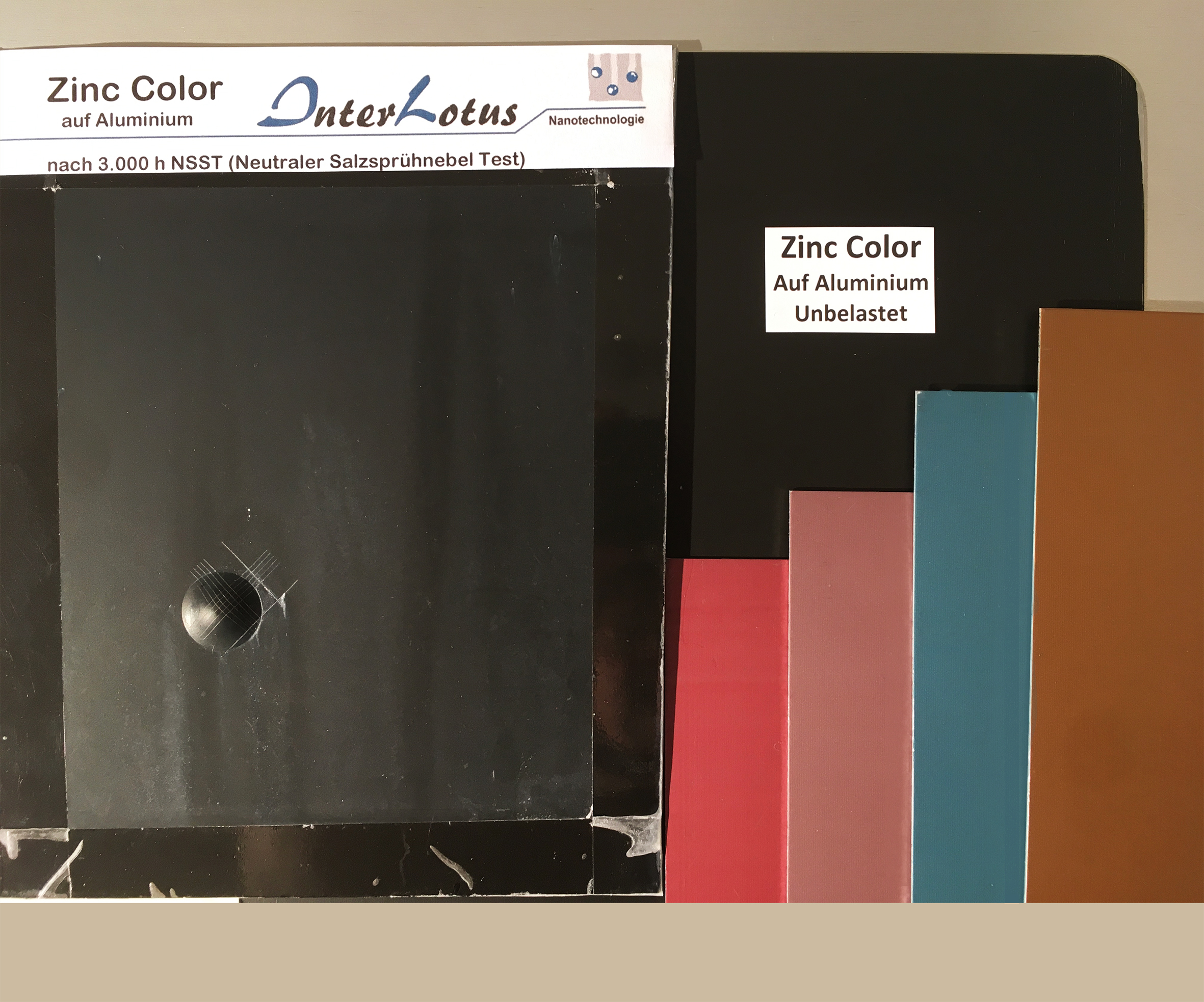

Therefore, Interlotus has developed thin-layer, long-lasting corrosion protection coatings especially for phosphated surfaces. We have also developed coil-coating paints for various applications on bright rolled zinc surfaces with extreme long-term corrosion protection (NSST > 2.000 h).

InterLotus HPC Color – Bright Rolled Zinc

InterLotus HPC – High Performance Coating can be applied directly onto bright rolled zinc sheet. The coating process is environmentally friendly and saves resources. The phosphatisation can be eliminated. You save costs, time and material

Test methods / Quality assurance

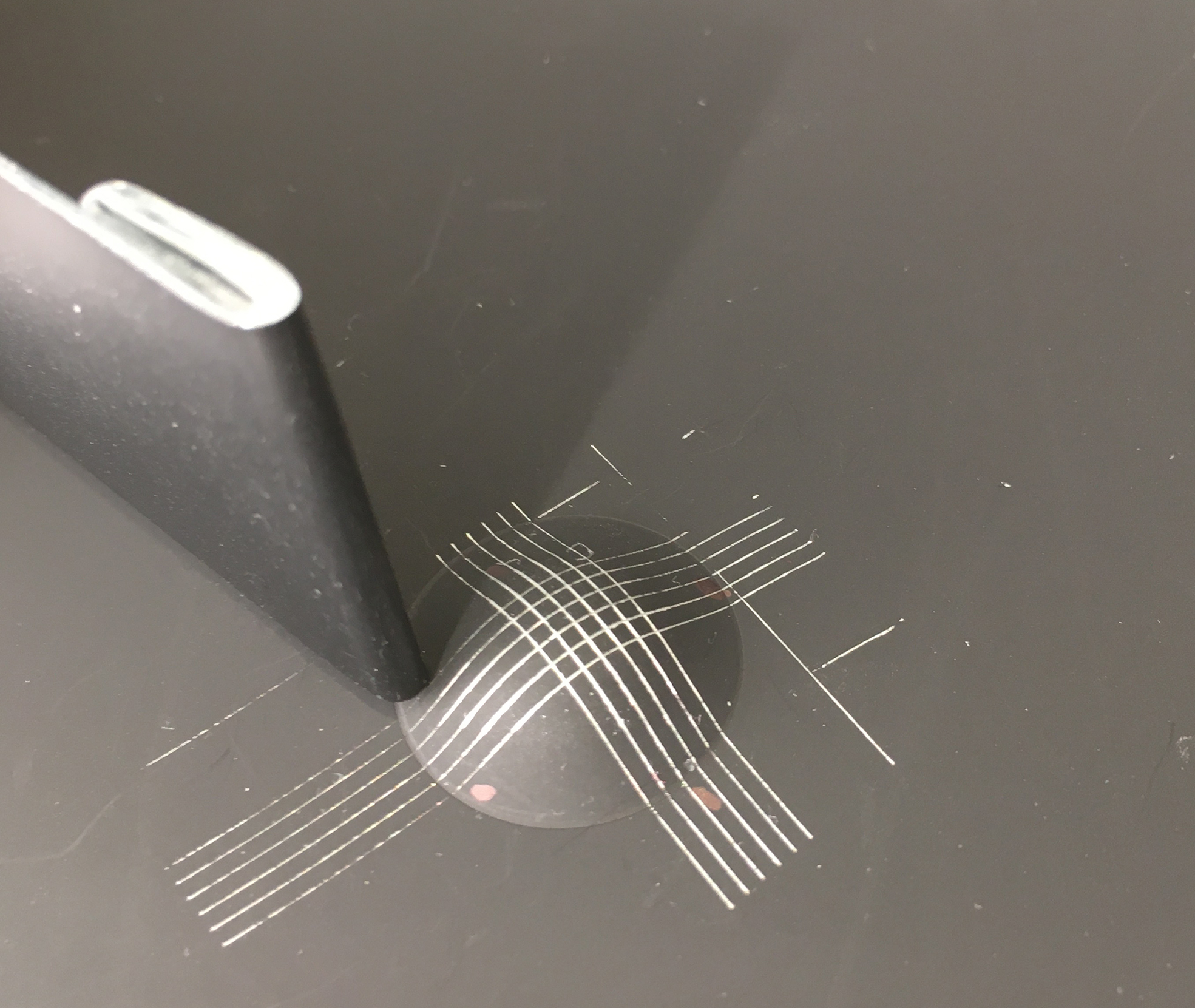

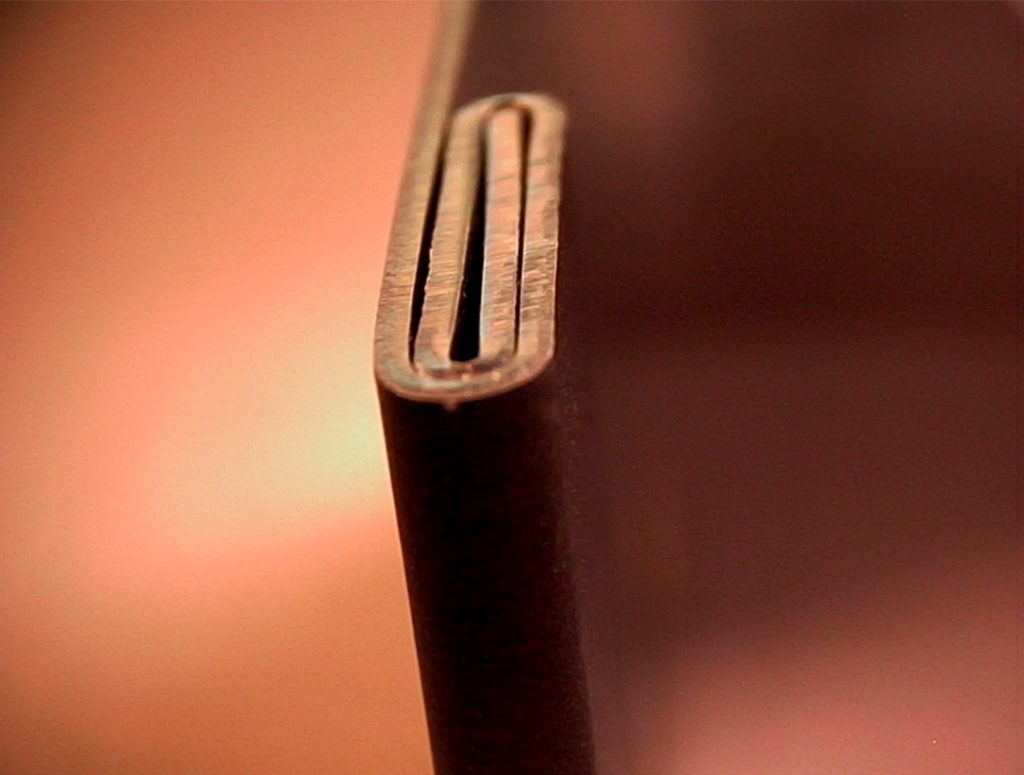

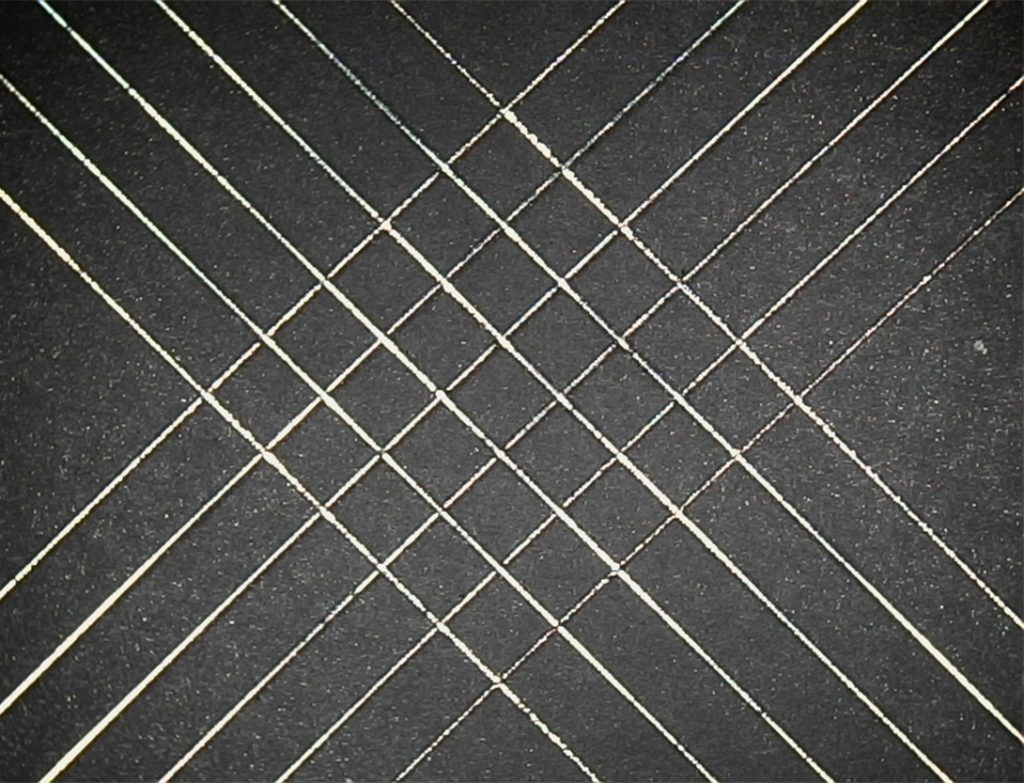

Test Methods – Cross Cut / Erichsen Deepening / T-Bend Test

The adhesion, delamination and flexibility of Interlotus coatings are tested with all test methods. In the T-bend test, we test the flexibility and adhesion of the coating. All Interlotus Coating relevant test methods are performed in our own in-house Technical Centre & Laboratory.

Laboratory & Testing

Interlotus “High Performance Coatings” are individually developed and formulated in our own laboratory. This is how our nano-modified hybrid systems are created.

Scratch test, T-bend test

Tests in the pilot plant & laboratory, dispersion tests, color measurements, laboratory passivation, scratch resistance.